Showroom

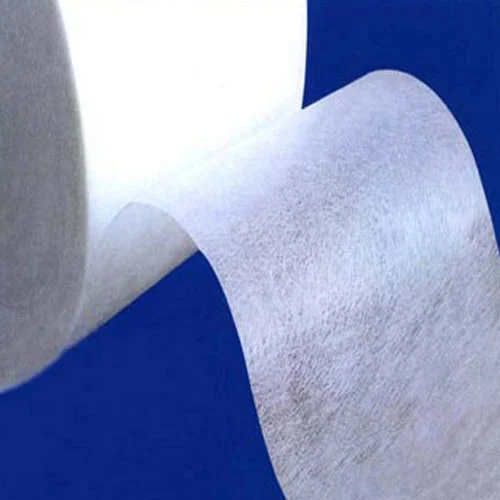

Acoustic Insulation products supplied by our company help to eliminate the excessive noise and echoes. These elements are made up of micro porous materials that offer excellent sound trapping properties that make them highly demanding among our clients.

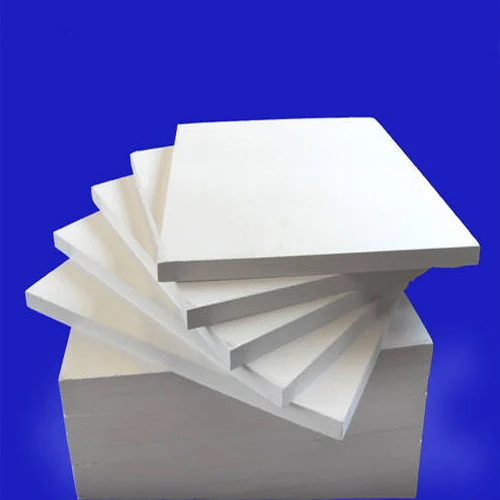

Thermal Insulation products manufactured and supplied by our company are made up of best in class moisture and chemical resistance. Buy from us these heat insulations materials from our company at a reasonable and low price range.

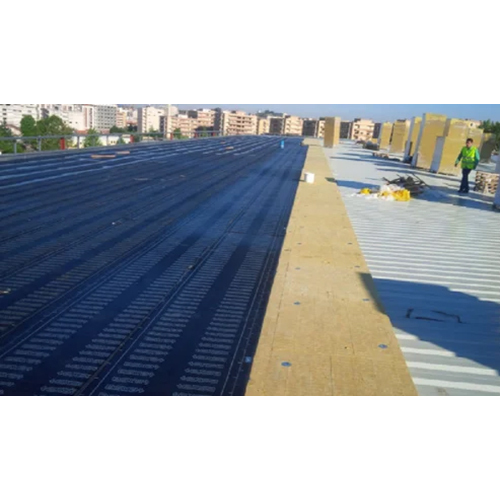

Our company offers various types of Hot Insulation materials that are commonly used in insulation of rooftops and other structures to prevent the entry of high temperature heat waves. Get this top-grade insulated element form our company at a reasonable and low price range.

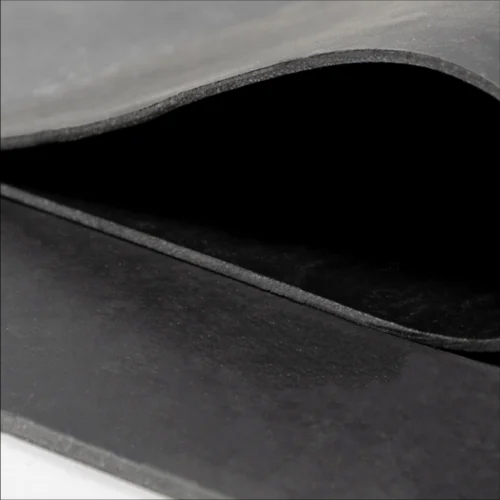

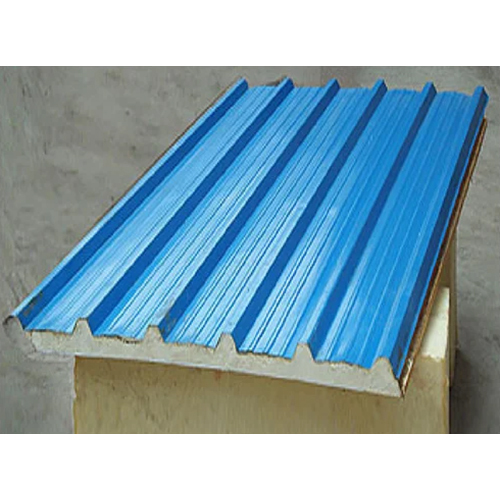

Kavita Trading Co deals in the supplying and exporting of premium grade Cold Insulation elements that are specially designed to provide excellent insulating effects to maintain energy levels. These components are commonly used in cold storages and other application areas.

Kavita Trading Co is a Maharashtra, India-based manufacturers and suppliers of top-grade Under Duct Insulation formulas that are prepared by using top-grade ingredients that are added in highly proportionate amounts that result in high bonding strength and excellent thermal resistance.

Buy from our premium range of Pidilite Products that are commonly used as an adhesive to make strong bonds between similar as well as dissimilar elements. These bonding agents are highly demanding among our customers due to their high bonding strength, chemical, and water resistance.

Send Inquiry

Send Inquiry Send SMS

Send SMS